There are times I wonder why I didn’t go the mechanical engineering route. It is so much fun.

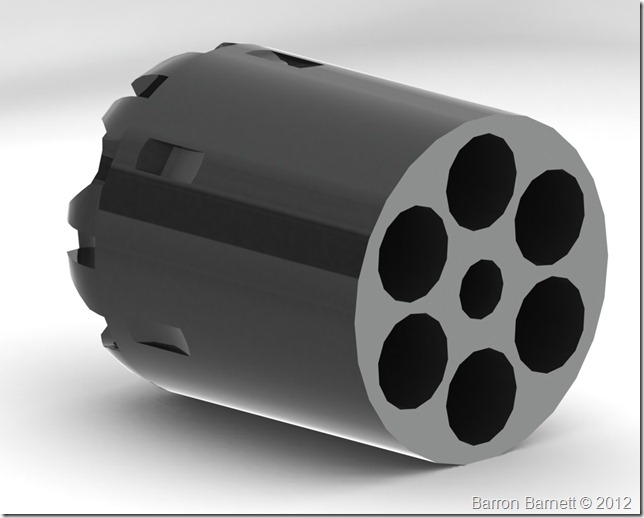

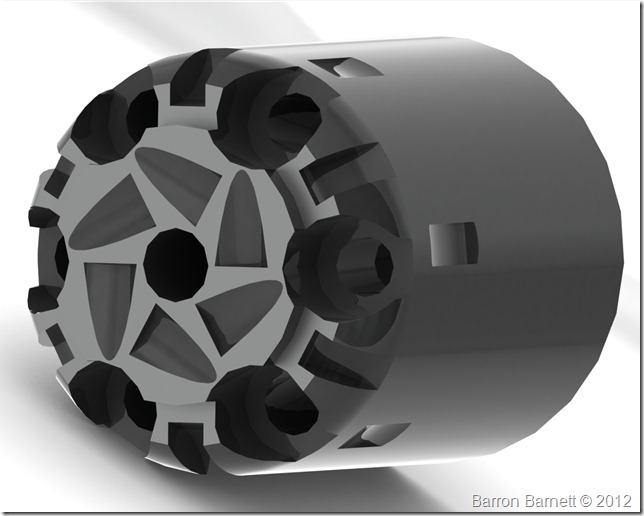

I spent today modeling the cylinder of a cap and ball revolver loaned to me by a friend. For the most part I’m happy with the results. The only thing I’m not really happy with is the cylinder incrementing on the recoil pad.

Getting the precise dimensions for the correct location and depth was quite difficult. The measurements are quite close, but not 100% there. It will take some more tweaking.

I also need to pull one of the nipples and take the measurements to make sure I have the interior threading specified correctly. I think I might actually model the threads at some point too, just for grins.

If anyone wants to try and guess the type of revolver based off the cylinder feel free. No prizes, just ultimate bragging rights.

TMM is the owner, editor, and principal author at The Minuteman, a competitive shooter, and staff member for Boomershoot. Even in his free time he’s merging his love and knowledge of computers and technology with his love of firearms.

Many know his private name and information however due to the current political climate, many are distancing themselves due to the abandonment of Due Process.

What software are you using for your modeling? Do you plan to CNC it out??

My guess is going to be a Colt Navy revolver

That is a rendering out of Solidworks. The owner has had 0 luck getting any mechanical drawings of this model. In the end we will probably have some of the parts printed before moving forward with some of the other goals with this project. This is merely a starting point.

Negative on the Colt, and negative on the Navy. A side hint, Eastwood is quite familiar with it.

Haven’t played with Solidworks, though it may come into play a few years from now if the grip making takes off. I have visions of composite metal/wood grips and would need the CNC for the metal portions.

Did not know that about the Remington, learn something new every day.

I didn’t know about it either till it was handed to me. Then upon reading about it all I could think was, “How the hell did I not know it by name or sight?”

I have a couple projects in the wings that I might move in to. Grips is one of them. First we need to get Janelle’s side of things done being boot strapped.

1858 Remington. You can tell by the “safety notches” between the cylinders–the hammer can rest there, so you can safely load all of the cylinders

Correct senior! You win the prize of bragging rights!

The safety notches and the flat surface cylinder “star” are dead giveaways. The Colt’s revolvers of the same period have stars that would look familiar to modern wheelgun owners.

I don’t think the star notches need to be exact, so long as the pushed surfaces are in the right place relative to the chambers, and the contact angles are about the same. In real life, if the bolt ends up in the bolt notches and the hammer gets to full cock, you’re good to go.

No pressure, as long as it’s all perfect forever and it works as smooth as silk.